Sensors and Transmitters

-

Smoke Opacity Monitoring System JC-30D2-EZ

Model JC-30D2-EZ, Smoke Opacity Monitoring System - Microprocessor-based indicating instrument with a smoke duct mounted optical sensing assembly. The system provides a continuous opacity readout, alarm indication, and shutdown capability.

-

.png)

3-Stack Smoke Opacity Monitor JC-33D2

The JC-33D2 Smoke Opacity Monitor assures accurate measurement of smoke emissions from boilers, incinerators, kilns, and similar sources of intermittent, visible emissions as well as an alarm contact that energizes when opacity exceeds a predetermined setpoint.

-

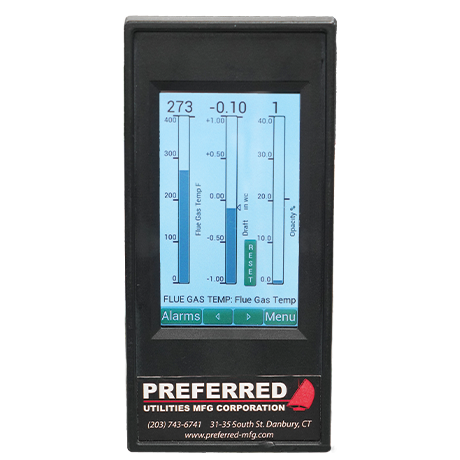

3-in-1 Digital Process Monitor JC-13D2

3-channel Process Bargraph Indicator and Alarm Monitor - Microprocessor based indicator alarm that can be field configured for a wide variety of applications.

-

JC-23D2 Flue Temperature, Opacity and Draft Controller

The JC-23D2 3-in-1 Flue Temp, Opacity and Draft controller maintains the flue gas at a constant positive or negative Draft by modulating the outlet damper on a boiler or furnace while also monitoring flue gas temperature and stack opacity.

-

Flue Gas Temperature Monitor JC-15D2

Flue gas temperature is continuously displayed using a highly visible backlit LCD display. An intuitive bar graph display and alarm messages provide clear stack temperature status.

-

JC-43D2 3-Element Drum Level Controller

The JC-43D2 3-Element Drum Level Controller maintains a boilers drum level at setpoint by modulating a 4-20 mA control output with a user selectable 1-element, 2-element, or 3-element PID loop.

-

.png)

In-Situ Oxygen Sensor

Detector consists of a zirconium oxide cell, a ceramic heater with thermocouple, terminals for connecting to the controller unit, a flange for connection to the probe, opening to accept reference (ambient) air and a connection for calibration gas.

-

Draft Controller JC-22D2

Model JC-22D2, Draft Monitor and Controller - Microprocessor based draft controller, indicating instrument, and alarm monitor. The JC-22D2 directly accepts a 4-20 mA draft transmitter signal, 120 VAC flame safeguard interface, and outputs a solid state switching (Triac) or 4-20 mADC outlet damper actuator control signal.

-

Draft Range Transmitter Assembly

Model JC-22XMTR, Draft Transmitter with Low Draft Cutout Switch - Field mountable boiler draft range transmitter and independent high pressure cut-out switch with 5 second time delay relay.

-

Pressure Transmitter

Pressure Transmitter with Siphon Loop - Specifically designed for industrial applications and typical industrial grade environments. Standard features are tailored for applications involving extreme environmental conditions and those that require more stringent performance needs.

-

.png)

Draft Range Differential Pressure Switch

The JC-22-HDPCO-8 is a draft range differential pressure switch with red warning light and time-delayed cutout relay contacts.

-

Digital Process Monitor JC-10D2

Model JC-10D2, Process Bar Graph Indicator and Alarm Monitor - Microprocessor based indicator alarm that can be field configured for a wide variety of applications. The instrument provides a highly visible color touchscreen with easy to understand bar graph, scaled numeric display, and front panel alarm messages.